- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

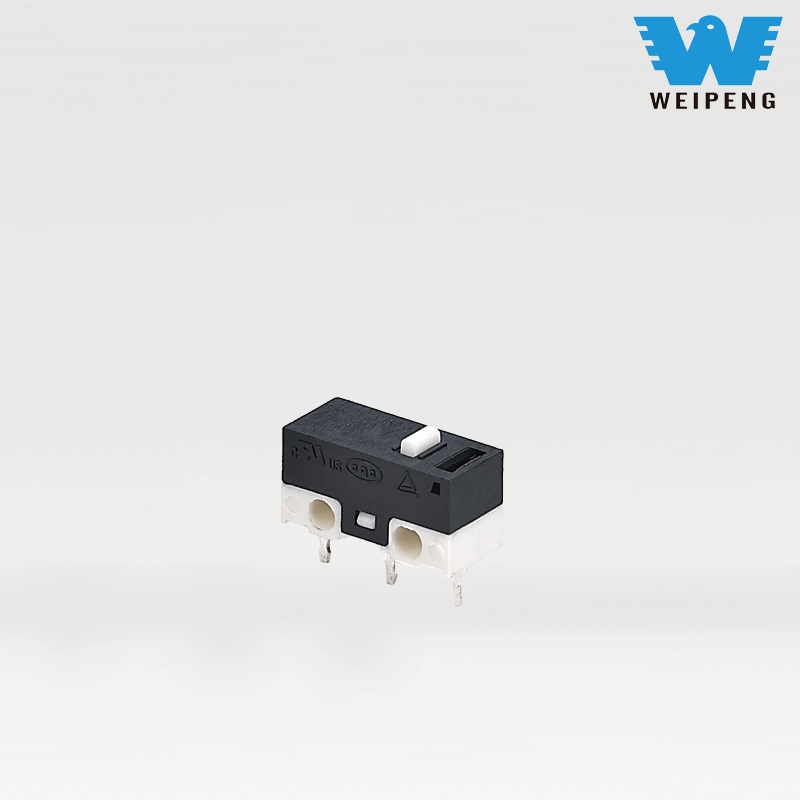

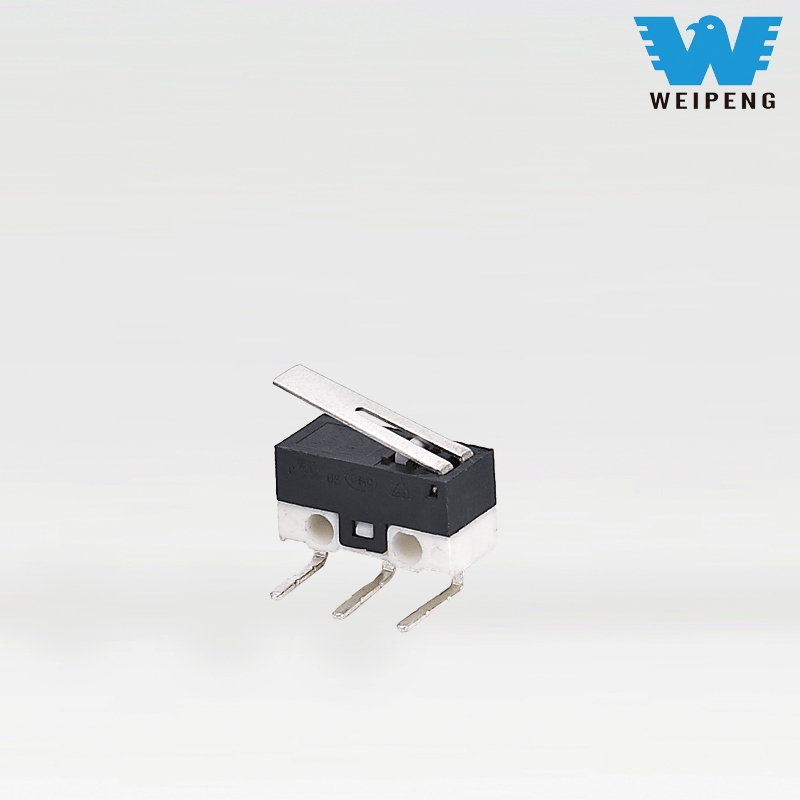

Micro Switch Mouse Establishes A Superior Control Experience

In fields such as esports, office work, and industrial control, the precise control and durability of a mouse directly affect user experience. As the core component of a mouse, the Micro Switch Mouse is the key to determining its click feel, response speed, and service life. Yueqing Tongda Wired Electric Factory, which has been deeply engaged in the switch industry for over 30 years, provides high-quality core components for global mouse manufacturers through its dedicated R&D and precision manufacturing of Micro Switch Mouse, becoming an important force in promoting the upgrading of control experience in the mouse industry.

Since its establishment in 1990, Yueqing Tongda Wired Electric Factory has always been guided by the principle of "accurately controlling core components to empower the upgrading of end products", gradually focusing on segmented fields from early general-purpose micro switches. With the boom of the esports industry and the increasing demand for mouse performance in office scenarios, users' demand for "no click delay, stable pressing feel, and no double-click failure after long-term use" has become increasingly urgent. Relying on its miniaturization and high-sensitivity characteristics, the Micro Switch Mouse was designated as a key R&D main product by the factory. After nearly a decade of technical refinement, the factory has formed a Micro Switch Mouse product matrix covering esports-grade, office-grade, and industrial-grade products, and has become one of the few enterprises in the industry capable of meeting the three major demands of "long service life, low actuation force, and fast response" simultaneously.

Technological innovation is the core competitiveness of Yueqing Tongda Wired Electric Factory's Micro Switch Mouse. The R&D team has carried out a number of technical researches to address the pain points of traditional mouse micro switches, such as "fast attenuation of click feel, high actuation delay, and easy double-click failure": In terms of contact material, high-hardness silver alloy contacts are adopted, which have been treated with a special electroplating process to reduce the contact wear rate by 40%. This enables the click life of a single micro switch to reach more than 5 million times, far exceeding the industry's conventional standard of 3 million times; In terms of structural design, an innovative "dual-spring reset structure" is adopted, optimizing the actuation stroke to 0.6-0.8mm. This not only ensures clear click feedback but also shortens the actuation delay, meeting the fast operation needs in esports scenarios.

To meet the needs of different scenarios, the factory provides a variety of customized solutions for Micro Switch Mouse. For esports mice, it has launched a "high-elasticity actuation model" with a pressing force controlled at 50-60g to meet the fast rebound needs of high-frequency clicks; For office mice, it has developed a "mute model", which reduces the click noise to below 30 decibels by optimizing the contact collision structure, adapting to quiet office environments; For industrial control mice, it has created a "high and low temperature resistant model" that can work stably in environments ranging from -40℃ to 85℃, suitable for extreme scenarios such as factory workshops.

Quality control runs through the entire production process of Micro Switch Mouse and is the "lifeline" of Yueqing Tongda Wired Electric Factory. In the raw material link, strict screening is conducted on core components such as silver alloy contacts, springs, and plastic shells, and only suppliers that meet the EU RoHS environmental standards are selected; In the production link, fully automated precision assembly equipment is introduced to control the component assembly error within 0.02mm, avoiding the feel deviation caused by manual operation; In the testing link, each batch of products must undergo three core tests: "click life test", "actuation force consistency test", and "electrical performance test". The life test simulates actual click scenarios and verifies durability through continuous pressing; The force test uses a high-precision pressure sensor to ensure that the actuation force deviation of products in the same batch does not exceed 5g; The electrical test detects the on-resistance and insulation performance to ensure safe use.

Facing the development trend of "wireless, lightweight, and intelligent" in the mouse industry, Yueqing Tongda Wired Electric Factory is accelerating technological upgrading. On the R&D side, it has launched the "miniaturized low-power Micro Switch Mouse" project, planning to reduce the switch volume by 20% and lower power consumption by 15% to meet the battery life needs of wireless mice; At the same time, it is exploring the integration of pressure sensing technology into micro switches to realize "different actuation forces triggering different functions", helping to make mouse control more intelligent. On the production side, it is promoting the construction of "digital workshops", realizing full-process data traceability through the MES production management system, and further improving production efficiency and product consistency.

In the future, Yueqing Tongda Wired Electric Factory will continue to take the Micro Switch Mouse as its core, adhere to the concept of "precision manufacturing and innovation empowerment", continuously break through industry technical bottlenecks, provide more durable, sensitive, and scenario-adaptable core components for global mouse manufacturers, and continuously promote the mouse control experience to a higher level of upgrading.