- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

With Micro Switch as the Core, Laying a Solid Foundation in the Precision Control Field

2025-09-01

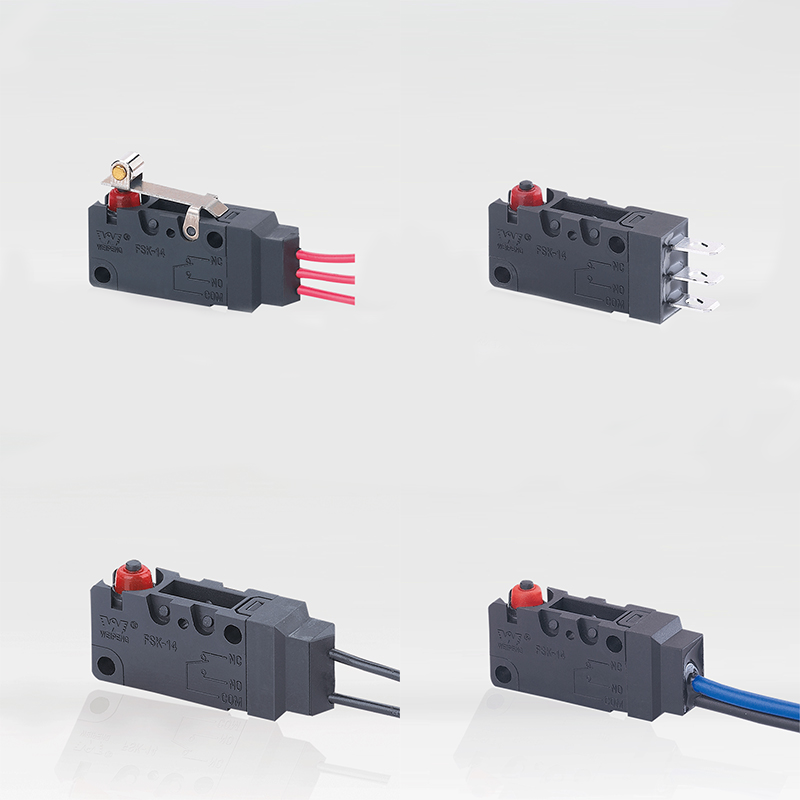

In fields such as smart homes, industrial automation, and medical equipment, Micro Switch has become a key component for achieving precise control, thanks to its "high sensitivity and miniaturization" characteristics. Yueqing Tongda Wired Electric Factory, which has been deeply engaged in the switch industry for more than 30 years, provides reliable precision control solutions for various industries through its dedicated R&D and precision manufacturing of Micro Switches, and has become an important force in promoting the localization development of micro switches.

Since its establishment in 1990, Yueqing Tongda has always been guided by the principle of "technology adapting to scenario needs", gradually focusing on the segmented field of Micro Switch from general-purpose switches in the early days. As equipment upgrades towards "miniaturization and high precision", the market's requirements for Micro Switch in terms of "trigger accuracy, service life, and stability" have become increasingly strict. The factory quickly set up a special R&D team and listed Micro Switch as a core main product for key research. After years of technical accumulation, it has formed a Micro Switch product system covering 1A-5A current and 3V-250V voltage, which can meet the diverse control needs from micro sensors to large industrial machinery.

Technological innovation is the core competitiveness of Yueqing Tongda's Micro Switches. Aiming at the pain points of traditional micro switches such as "trigger delay, short service life, and vulnerability to environmental interference", the R&D team has carried out targeted optimizations: In terms of contact design, silver alloy material is used and treated with a special electroplating process to reduce contact resistance, increasing the electrical service life of the switch to more than 500,000 times; In terms of structure, an innovative "dust-proof and splash-proof sealing design" is adopted, and some products have reached IP60 protection level, which can work stably in humid and dusty industrial workshops; In terms of sensitivity control, the trigger stroke is precisely calibrated to 0.1-0.3mm, meeting the scenarios with extremely high control accuracy requirements such as medical equipment.

To meet the needs of different industries, the factory provides flexible customized services. For the smart home field, it has developed "low-power Micro Switches", reducing standby power consumption by 30% to meet the battery life needs of wireless smart devices; For the industrial automation field, it has launched "high and low temperature resistant models", which can operate normally in environments ranging from -40℃ to 85℃; For the medical equipment field, it uses medical-grade environmentally friendly materials and has passed biocompatibility tests to ensure safe use. Previously, the Micro Switch customized for a medical equipment enterprise, relying on its "high-precision trigger + low noise" characteristics, helped the enterprise's products pass international certifications and gain recognition in overseas markets.

Quality control runs through the entire production process of Micro Switches. In the raw material link, metal contacts, engineering plastics and other components that meet RoHS standards are carefully selected, and each batch undergoes component testing; In the production link, fully automated precision assembly equipment is introduced to control the component assembly error within 0.01mm, avoiding deviations caused by manual operations; In the testing link, each switch must pass three core tests: "trigger accuracy test, service life test, and insulation performance test", ensuring that the qualification rate of delivered products reaches 100%. With strict quality control, the products have passed authoritative certifications such as UL, VDE, and CQC, and have become qualified suppliers for enterprises such as Midea, Haier, and BYD.

Facing the industry trend of "intelligence and miniaturization", Yueqing Tongda is accelerating technological upgrading. On the R&D side, it is exploring the integration of sensor technology into Micro Switches to realize the integration of "control + data collection"; On the production side, it is promoting the construction of "digital workshops" and realizing full-process data traceability through the MES system, improving production efficiency by 25%. In the future, the factory will continue to take Micro Switch as the core, adhere to the concept of "precision manufacturing", provide more reliable and intelligent precision control components for global customers, and promote the innovative development of the micro switch industry.