- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

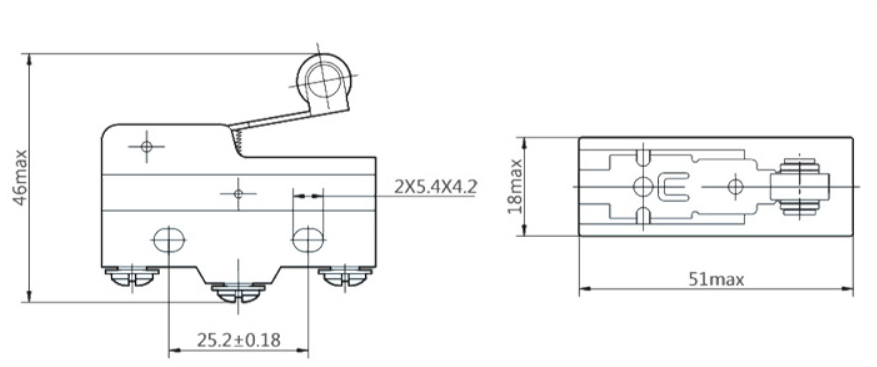

Self-Resetting Pressure Limit Stroke Micro Switch

Self-Resetting Pressure Limit Stroke Micro Switch, as a control element triggered by mechanical displacement, plays a core role in precisely controlling the movement boundaries of equipment, achieving automated start-stop or safety protection, and is widely applicable in various fields such as industry, home appliances, and transportation.

Model:LS-01-003

Send Inquiry

Switch Introduction

The travel limit switch is triggered mechanically, and the action of the contacts is used for control: when the moving parts of the equipment move to a preset position and touch the triggering mechanism of the switch (such as a roller or lever), it drives the internal mechanical structure to interact, causing the normally open/normally closed contacts of the switch to switch between on and off, thereby cutting off or connecting the control circuit to realize the start and stop of the equipment, limit protection, or process switching.

Switch Application

In equipment such as lathes, milling machines, and machining centers, limit switches are commonly installed at both ends of the guide rail or at the extreme positions of the sliding table. For instance, on the tool holder moving track of a CNC lathe, when the tool holder approaches the end of the track, the switch is triggered to cut off the motor power, preventing the tool holder from exceeding its travel and colliding with the machine body. Similarly, when the working table of the milling machine moves sideways or back and forth, the switch accurately controls the movement boundaries, preventing interference between the workpiece and machine components, thereby protecting the cutting tool and ensuring machining precision.

Switch Details