- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Micro switch drives the precision control of Yueqing Tongda

2025-09-12

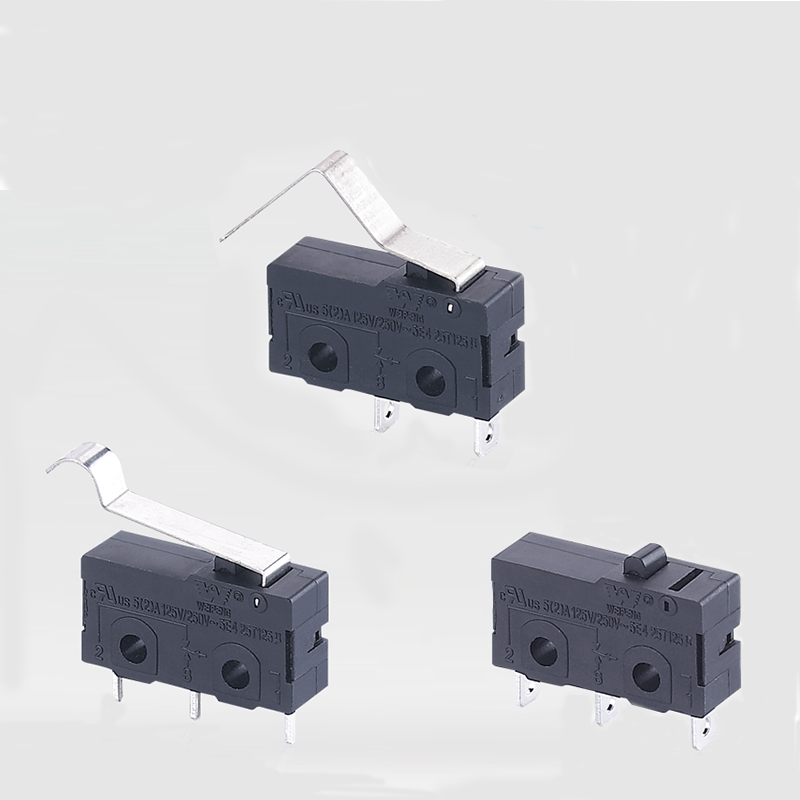

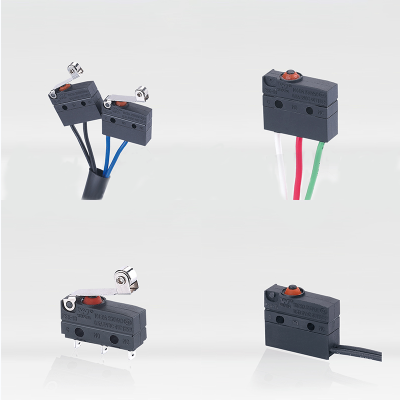

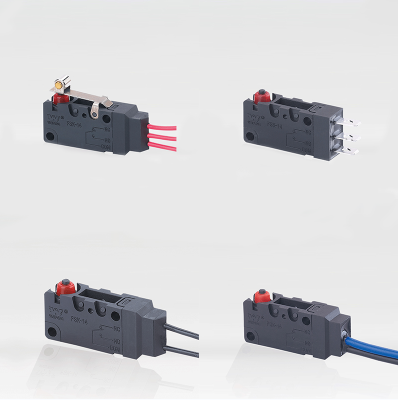

In the field of precision control such as smart home sensors, industrial automation equipment, and medical monitoring instruments, a micro switch with a volume of only a few cubic centimeters directly determines the response accuracy and operational safety of the equipment. Yueqing Tongda Wired Electric Factory, which has been deeply engaged in the switch industry for more than 30 years, relies on its dedicated R&D and precision manufacturing of Micro Switches. It not only breaks through the pain points of traditional products such as "short service life, vulnerability to interference, and poor scenario adaptability" but also builds a precision control solution covering multiple industries, becoming a core supplier in the domestic Micro Switch field.

Looking back at its development history, the in-depth integration of Yueqing Tongda with Micro Switches stems from its keen capture of market demand. When the factory was established in 1990, it mainly produced general-purpose switches. However, as electronic equipment upgraded towards "miniaturization and high precision", traditional switches gradually failed to meet the strict requirements of medical, industrial and other fields due to large trigger errors and weak environmental resistance. Since 2010, Yueqing Tongda decisively listed Micro Switches as its core main product and set up a 10-person special R&D team. It made breakthroughs one by one in contact material, structural design and protection technology. After 5 years of iteration, it finally formed a product matrix covering 1A-5A current and 3V-250V voltage, which is suitable for more than 20 scenarios ranging from smart door lock buttons to industrial machinery limit control.

Technological innovation is the "key to breaking the situation" for Yueqing Tongda's Micro Switches. Aiming at the industry problems of traditional micro switches such as "contact oxidation leading to failure and unstable trigger stroke", the R&D team proposed targeted solutions: the contacts are made of high-purity silver-palladium alloy, which is treated by vacuum sputtering process to reduce the oxidation rate by 60%, increasing the electrical service life of a single switch from the industry's conventional 300,000 times to 500,000 times; in terms of structure, an innovative "dual-spring sheet linkage design" is adopted, and the trigger stroke error is controlled within ±0.05mm through laser calibration. Even in a low-temperature industrial environment of -40℃, it can still maintain an accurate trigger range of 0.1-0.3mm. What's more noteworthy is that its independently developed "dust-proof and splash-proof sealing process" enables some Micro Switches to reach IP67 protection level, successfully solving the waterproof problem in scenarios such as kitchen appliances and outdoor sensors.

Scenario-based customization makes Yueqing Tongda's Micro Switches more attractive in the market. For the smart home field, it has launched a "low-power model" with a standby power consumption as low as 5μA, which meets the long battery life needs of wireless smart devices; for medical equipment, it has developed a "mute model", which controls the trigger noise below 25 decibels through a silicone buffer structure to avoid interfering with the ward environment; the "shock-resistant model" dedicated to the industrial field uses a zinc alloy shell and shock-proof springs, which can withstand high-frequency vibrations of 1000Hz and has been widely used in the limit control of CNC machine tools. Previously, the Micro Switch customized for a medical equipment enterprise for heart rate monitors, relying on its "high-precision trigger + medical-grade environmentally friendly materials", helped the product pass the EU CE certification and successfully enter the European market.

Strict quality control is the guarantee of product reputation. In the production workshop of Yueqing Tongda, Micro Switches need to go through "three tests": in the raw material link, each batch of silver-palladium alloy contacts must pass component spectral testing; in the production link, fully automated assembly equipment controls the component assembly error within 0.01mm; in the finished product testing link, each switch must complete 500,000 press tests, 72-hour high-low temperature cycle tests and insulation resistance tests to ensure a 100% factory qualification rate. Today, its Micro Switches have passed three major international certifications: UL, VDE and CQC, and have become long-term suppliers for well-known enterprises such as Midea, Haier and Germany's Augan.

Facing the industry trend of "intelligence and miniaturization", Yueqing Tongda is accelerating the technological upgrading of Micro Switches. At present, the R&D team has launched the "Micro Switches with Integrated Sensor Function" project, planning to integrate the pressure sensing module into the switch to realize the integration of "control + data collection"; on the production side, it is promoting the construction of a "digital workshop", realizing the whole-process traceability from raw materials to finished products through the MES system, and improving production efficiency by 25%. In the future, Yueqing Tongda will continue to focus on Micro Switches as its core, deepen its presence in the precision control field, and provide more intelligent and reliable core components for global customers.