- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

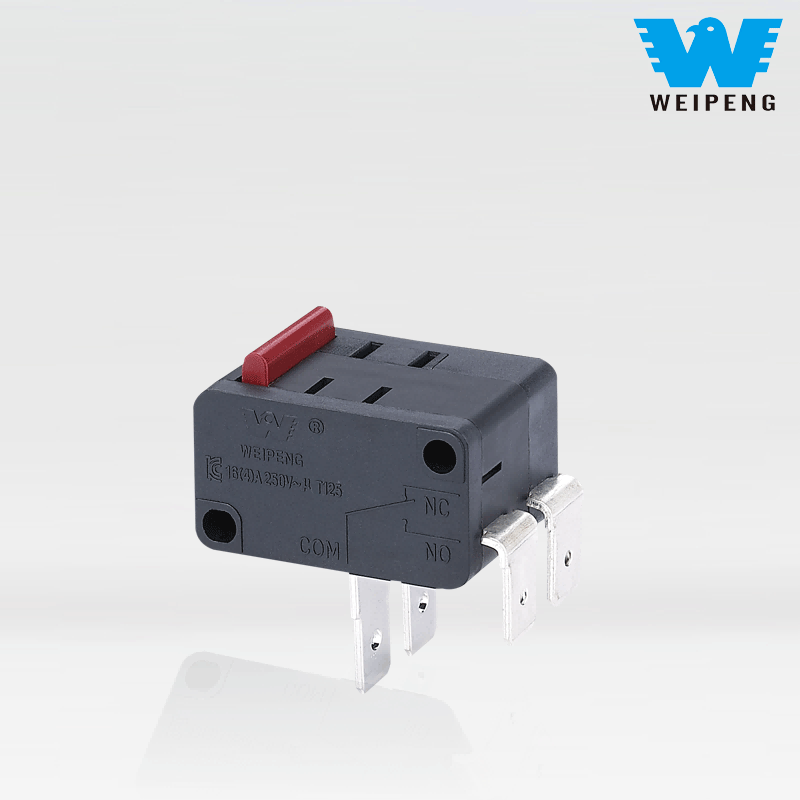

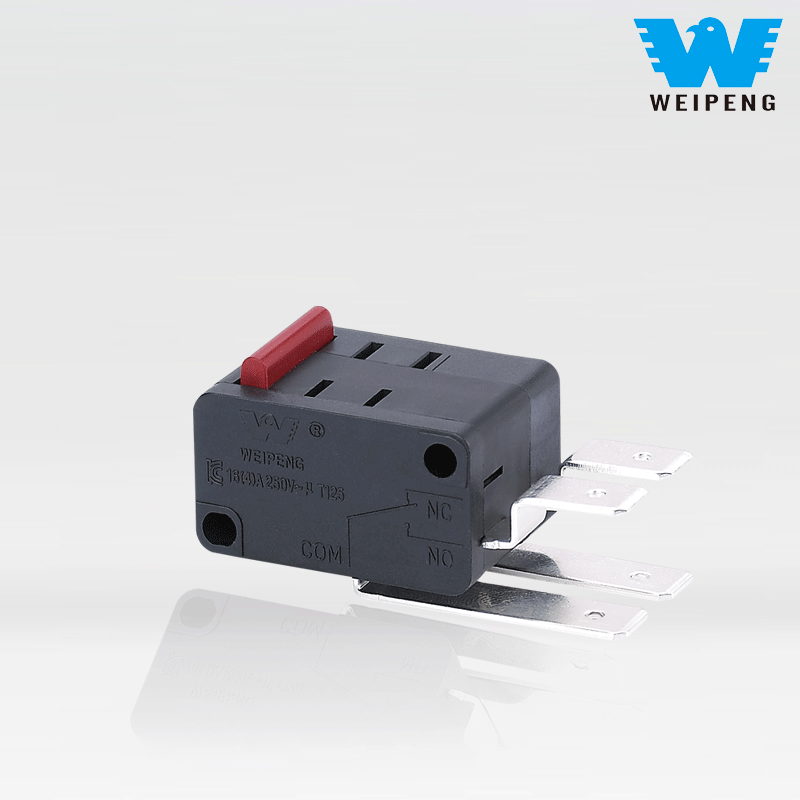

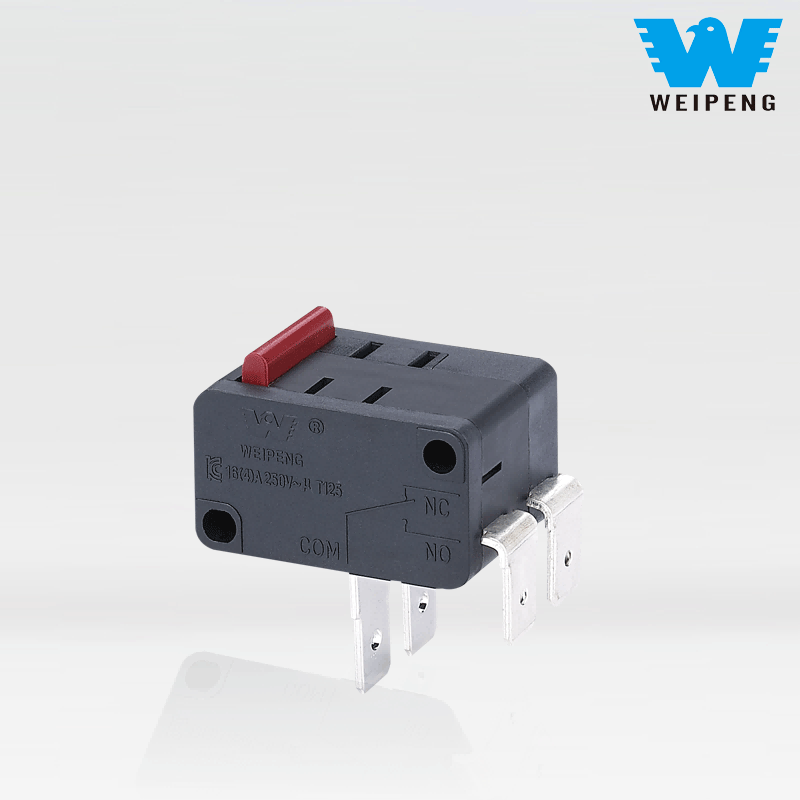

HK-14 Dual 6-Pin Motor Forward and Reverse Limit Switch

As the benchmark model of Yueqing Tongda Wire Electric Factory's micro switch series, the HK-14 Dual 6-Pin Motor Forward and Reverse Limit Switch features "high sensitivity, ultra-long lifespan, and multi-scenario adaptability" as its core advantages. Integrating the company's 35 years of switch manufacturing expertise, it has become a key control component in household appliances, automotive electronics, industrial automation, and other fields, thanks to its minimal contact gap and rapid action mechanism. Its performance and reliability have been certified by multiple authoritative organizations worldwide, securing its mainstream position in the niche market.

Model:HK-14-1X-16AP-1157

Send Inquiry

Micro Switch Introduction

The HK-14 demonstrates strong competitiveness in technical specifications and is especially suited for high-frequency, high-precision control requirements. The contacts are made of highly conductive alloy materials, with an initial contact resistance of ≤30mΩ, capable of stably carrying currents from 5A to 25A, and compatible with multiple voltage scenarios including AC 125V/250V and DC 12V/24V, meeting various power needs from small household appliances to industrial equipment.

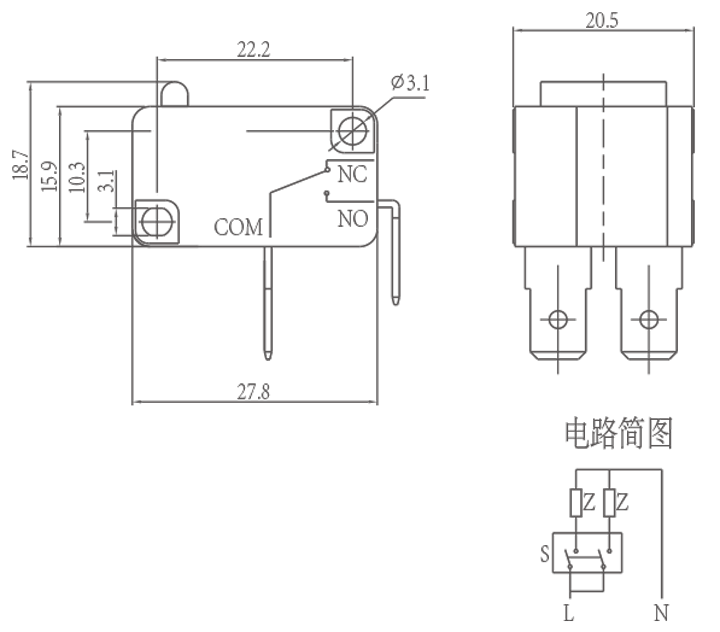

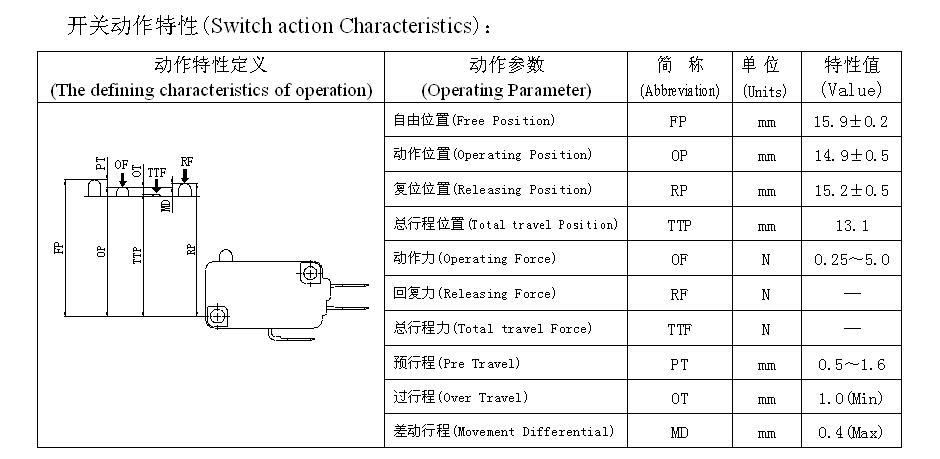

In terms of triggering performance, the product utilizes a snap-action mechanism, with an operating stroke of only 0.5-1.6mm and operating force controlled between 0.25-4N. It offers rapid triggering response and clear feedback, effectively avoiding issues of "false triggering" and "trigger delay." The lifespan far exceeds industry norms: mechanical life exceeds 1 million cycles, and electrical life reaches over 50,000 cycles, enabling long-term stable operation in high-frequency usage scenarios such as microwave ovens and automotive electronics.

The environmental adaptability is equally impressive. The product can operate in a wide temperature range from -25℃ to 125℃, pass a three-axis vibration test at 10-55Hz with an amplitude of 1.5mm, maintain an insulation resistance of ≥100MΩ (500VDC), and withstand a voltage of 1000V AC between terminals, ensuring stable performance even in industrial workshop vibration environments or the high-temperature conditions of a car engine compartment.

Relying on Leqing Tongda's full-process quality control system, the HK-14 undergoes multiple rigorous tests from raw materials to finished products:

Raw material testing: Contact material spectral analysis, spring piece elasticity and fatigue tests, and casing aging resistance tests to ensure core components meet automotive standards;

Production testing: Fully automated precision assembly lines equipped with visual inspection systems, controlling key dimensional errors within ±0.01mm to ensure consistent actuation accuracy;

Finished product testing: 100% pass rate for 10 tests, including high and low temperature cycling (-40℃ to 120℃), 48-hour salt spray corrosion, millions of pressing cycles, vibration and impact tests.

Micro Switch Parameter (Specification)

| Switch Technical Characteristics: | |||

| ITEM | Technical Parameter | Value | |

| 1 | Electrical Rating | 5(2)A/10A/16(3)A/21(8)A 250VAC | |

| 2 | Contact Resistance | ≤30mΩ Initial value | |

| 3 | Insulation Resistance | ≥100MΩ (500VDC) | |

| 4 |

Dielectric Voltage |

Between non-connected terminals |

1000V/0.5mA/60S |

|

Between terminals and the metal frame |

3000V/0.5mA/60S | ||

| 5 | Electrical Life | ≥50000 cycles | |

| 6 | Mechanical Life | ≥1000000 cycles | |

| 7 | Operating Temperature | -25~125℃ | |

| 8 | Operating Frequency |

electrical :15 cycles Mechanical :60 cycles |

|

| 9 | Vibration Proof |

Vibration Frequency : 10~55HZ; Amplitude :1.5mm; Three directions :1H |

|

| 10 |

Solder Ability : More than 80% of immersed part shall be covered with solder |

Soldering Temperature :235±5℃ Immersing Time :2~3S |

|

| 11 | Solder Heat Resistance |

Dip Soldering :260±5℃ 5±1S Manual Soldering : 300±5℃ 2~3S |

|

| 12 | Safety Approvals | UL、CSA、VDE、ENEC、TUV、CE、KC、CQC | |

| 13 | Test Conditions |

Ambient Temperature :20±5℃ Relative Humidity :65±5%RH Air Pressure :86~106KPa |

|

Micro Switch Feature and Application

2.Nice appearance,tight contiguration.Charactenistic:small contact dlearance,quick action, high sensitivity and small 3.operating travel.

4.Long lite, high reliablity

5.A variety of contact terminals

6.A varnety of temperature degree

7.A variety of levers

8.Adopt themosetting plastic or themoplastic

9.Widely usedinhome apliane elecroninc equipmentautomatic machine communication equioncar electron,apparatus and 10.instument,electric motion tool etc.

Micro Switch Details