- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Toy Water Gun with Waterproof Micro Switch

As the core product developed by Yueqing Tongda Cable Factory for special environments such as humidity, dust, and outdoor conditions, the FSK-18 series waterproof switches boast 'IP67 high protection and stable electrical performance' as their key advantages. Leveraging 35 years of switch manufacturing expertise, they feature various triggering modes, including rocker and button types, and are widely used in outdoor lighting, kitchen appliances, automotive electronics, industrial cleaning equipment, and other scenarios, making them a reliable choice for circuit control in harsh environments.

Model:FSK-18-004

Send Inquiry

Waterproof Micro Switch Introduction

The FSK-18 Series adopts a dual-protection structure of "integrated sealed housing + nitrile rubber seal ring": the housing is made of high-rigidity PA66 material, precision-molded with no seams at the joints; the seal ring is embedded in the housing groove, with a compression amount controlled between 0.3-0.5mm, achieving complete dust isolation (IP6X) and no leakage after 30 minutes of immersion in 1-meter water depth (IPX7). Test data shows that in scenarios such as kitchen oil spray, outdoor heavy rain washing, and industrial cleaning solution immersion, the moisture rate of internal components is 0, completely solving the problems of "water-induced short circuit and dust-induced jamming" of traditional switches.

Waterproof Micro Switch Feature and Application

1.Home & Commercial Scenarios:

Safeguarding Daily SafetyKitchen appliances: Suitable for dishwashers, built-in steam ovens, and under-sink water purifiers. The IP67 protection resists washing water splashes and oil contamination. After being equipped by a leading home appliance enterprise, the repair rate of water-induced product failures dropped from 12% to 0.3%;

Outdoor lighting: Used for power control of garden lights, lawn lights, and charging piles. Under -30℃ severe cold and 60℃ high-temperature exposure, the on-off response rate is 100%, and the service life is 3 times longer than that of ordinary switches.

2. Industrial & Automotive Scenarios:

Meeting Strict RequirementsIndustrial cleaning: Suitable for high-pressure cleaners and spray disinfection equipment. The chemical-resistant housing can resist the erosion of alkaline cleaning solutions. A food processing plant used it for 18 months with no corrosion or functional attenuation of the switch;

Automotive electronics: The customized model is used for car refrigerators and outdoor vehicle-mounted lighting. It has passed the vibration test of 10-55Hz (amplitude 1.5mm), and after 100,000 kilometers of driving,the actuation accuracy has no deviation, meeting the ISO 16750 standard for automotive electronics.

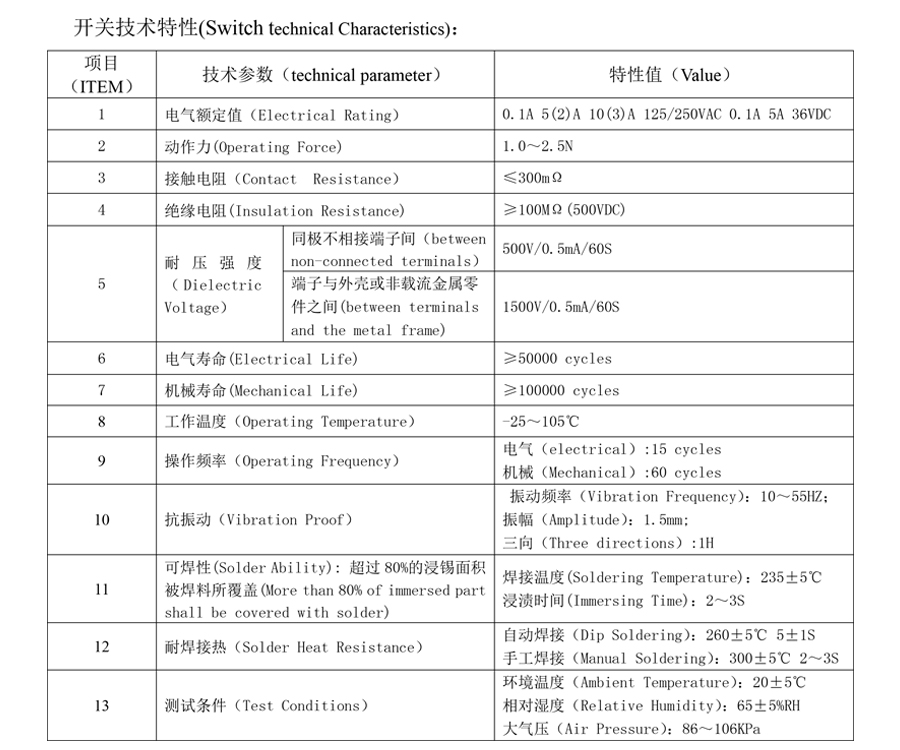

| Switch Technical Characteristics: | |||

| ITEM | Technical Parameter | Value | |

| 1 | Electrical Rating | 0.1A 5(2)A 10(3)A 125/250VAC 0.1A 5A 36VDC | |

| 2 | Operating Force | 1.0~2.5N | |

| 3 | Contact Resistance | ≤300mΩ | |

| 4 | Insulation Resistance | ≥100MΩ (500VDC) | |

| 5 |

Dielectric Voltage |

Between non-connected terminals |

500V/0.5mA/60S |

|

Between terminals and the metal frame |

1500V/0.5mA/60S | ||

| 6 | Electrical Life | ≥50000 cycles | |

| 7 | Mechanical Life | ≥100000 cycles | |

| 8 | Operating Temperature | -25~105℃ | |

| 9 | Operating Frequency |

Electrical :15 cycles Mechanical :60 cycles |

|

| 10 | Vibration Proof |

Vibration Frequency :10~55HZ; Amplitude :1.5mm; Three directions :1H |

|

| 11 |

Solder Ability : More than 80% of immersed part shall be covered with solder |

Soldering Temperature :235±5℃ Immersing Time :2~3S |

|

| 12 | Solder Heat Resistance |

Dip Soldering :260±5℃ 5±1S Manual Soldering :300±5℃ 2~3S |

|

| 13 | Test Conditions |

Ambient Temperature :20±5℃ Relative Humidity :65±5%RH Air Pressure :86~106KPa |

|

Tongda Waterproof Micro Switch Push Button Micro Details