- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Weipeng Car Seat Waterproof Micro Switch

As the professional manufacturers, WEIPENG® would like to supply Weipeng Car Seat Waterproof Micro Switch, we will offer you the best after-sale service and timely delivery. For more information on the 5A 125V/250VAC Waterproof Micro Switch, please feel free to contact us.

Model:FSK-14-1X-5A-003

Send Inquiry

Product Introduction

As the flagship waterproof switch developed by Yueqing Tongda for large industrial equipment and heavy-duty outdoor scenarios, the FSK-14 series is centered on 'heavy-duty compatibility and IP67-level deep waterproofing.' It combines the company's over 30 years of switch manufacturing experience with military-grade sealing technology. Specifically designed for high-power equipment, deep-water operations, and extreme industrial environments, it offers exceptional load capacity, deep-water sealing protection, and stable installation structure. It is widely adaptable to heavy machinery, power equipment, marine engineering, outdoor infrastructure, and other fields, becoming the core solution for controlling equipment in harsh environments.

The enclosure is made of high-strength PA66-GF30 reinforced nylon, which has been modified at high temperatures and treated for corrosion resistance. It features both flame retardancy (UL94 V-0) and anti-aging properties. Its operating temperature range covers -40°C to 105°C, allowing it to withstand high and low temperature cycling as well as high operating temperatures. The contact system uses silver alloy material, optimized through vacuum plating, with an initial contact resistance of ≤30mΩ, insulation resistance of ≥100MΩ (500VDC), and terminal voltage withstand of 2000V AC. This effectively prevents leakage, contact oxidation, and arc erosion in humid environments, improving the protection reliability by 40% compared to conventional large switches.

Product Feature and Application

Suitable for smart manufacturing production lines, PLC control boxes, robotic arm auxiliary control, and other scenarios. With IP67 protection, it can withstand workshop washdowns and dust corrosion. Its wide temperature performance adapts to workshop environments from -40℃ to 105℃. After being applied in a certain auto parts factory, the switch failure rate decreased by 65%, and equipment downtime was reduced by 50%.

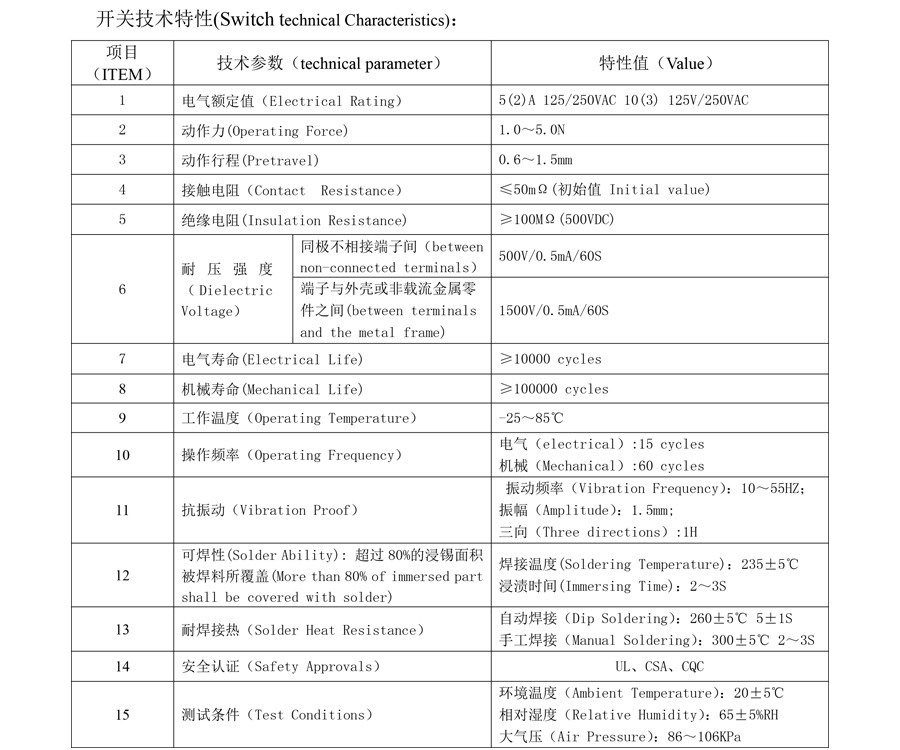

| Switch Technical Characteristics: | |||

| ITEM | Technical Parameter | Value | |

| 1 | Electrical Rating | 5 (2)A 125/250VAC 10(3) 125V/250VAC | |

| 2 | Operating Force | 1.0~5.0N | |

| 3 | Pretravel | 0.6~1.5mm | |

| 4 | Contact Resistance | ≤50mΩ Initial value | |

| 5 | Insulation Resistance | ≥100MΩ (500VDC) | |

| 6 |

Dielectric Voltage |

Between non-connected terminals |

500V/0.5mA/60S |

|

Between terminals and the metal frame |

1500V/0.5mA/60S | ||

| 7 | Electrical Life | ≥10000 cycles | |

| 8 | Mechanical Life | ≥100000 cycles | |

| 9 | Operating Temperature | -25~85℃ | |

| 10 | Operating Frequency |

Electrical :15 cycles Mechanical :60 cycles |

|

| 11 | Vibration Proof |

Vibration Frequency :10~55HZ; Amplitude :1.5mm; Three directions :1H |

|

| 12 |

Solder Ability : More than 80% of immersed part shall be covered with solder |

Soldering Temperature :235±5℃ Immersing Time : 2~3S |

|

| 13 | Solder Heat Resistance |

Dip Soldering :260±5℃ 5±1S Manual Soldering :300±5℃ 2~3S |

|

| 14 | Safety Approvals | UL、CSA、CQC | |

| 15 | Test Conditions |

Ambient Temperature :20±5℃ Relative Humidity :65±5%RH Air Pressure :86~106KPa |

|

Product Details

Relying on Yueqing Tongda's full-process industrial-grade quality control system, the FSK-14 undergoes multiple rigorous inspections from raw materials to finished products:

Raw Material Inspection: Contact material spectral analysis, spring fatigue strength testing, casing corrosion resistance testing, with core components certified to military-grade standards;

Production Inspection: Fully automated heavy-duty switch assembly line, key dimensional errors controlled within ±0.03mm, sealing performance 100% passed deep water immersion tests;

Finished Product Inspection: Fully passes 12 industrial-grade tests, including IP67 waterproof immersion, 1000 hours of salt spray corrosion, 50,000 durability presses, and 200Hz vibration shock.