- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

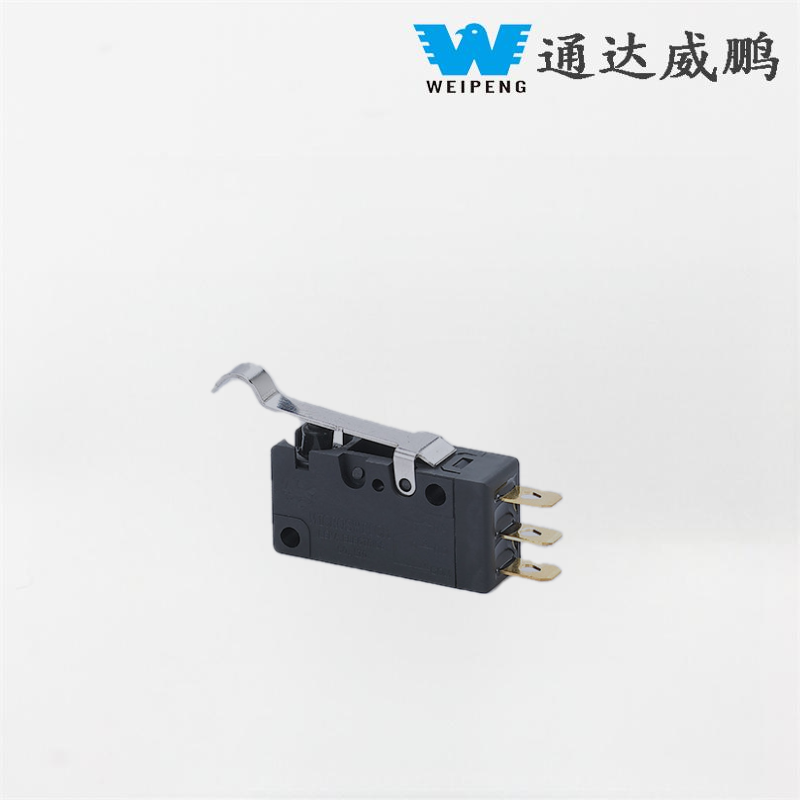

Weipeng Cleaning Equipment Waterproof Micro Switch

As the professional manufacturers, WEIPENG® would like to supply Weipeng Cleaning Equipment Waterproof Micro Switch, we will offer you the best after-sale service and timely delivery. For more information on the 5A 125V/250VAC Waterproof Micro Switch, please feel free to contact us.

Model:FSK-14-5A-010

Send Inquiry

Product Introduction

The FSK-14 features a dual protection design with 'precise sealing and upgraded materials,' fully meeting the IP67 international protection standard (IEC 60529), achieving comprehensive protection with 'completely dustproof and short-term immersion in 1 meter of water for 30 minutes.' Its sealing structure uses a single reinforced fluororubber gasket design, with the gasket diameter 0.2mm larger than the interface groove, forming a 30% compression after assembly, completely blocking the entry of moisture and dust. Meanwhile, the rear is tightly pressed against the cable through a PVC sleeve to prevent water from seeping in from the cable entry, perfectly suitable for workshop spray, short-term outdoor rain, and other scenarios without prolonged immersion.

Product Feature and Application

Adapted for start-stop control and travel limit of construction machinery, mining equipment, and heavy agricultural machinery, with IP67 protection to withstand mud, water immersion, and vibration impacts on construction sites. With a super wide load to meet engine start-stop requirements, it reduces control switch failure rates and maintenance costs after application.

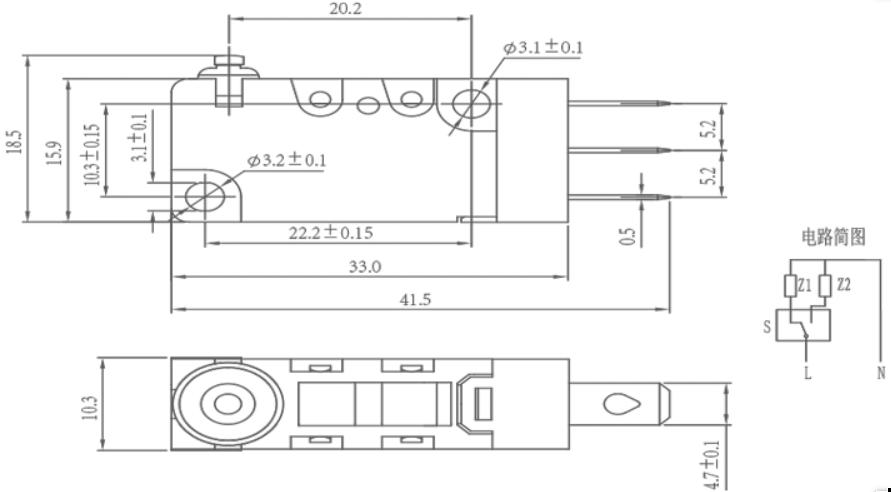

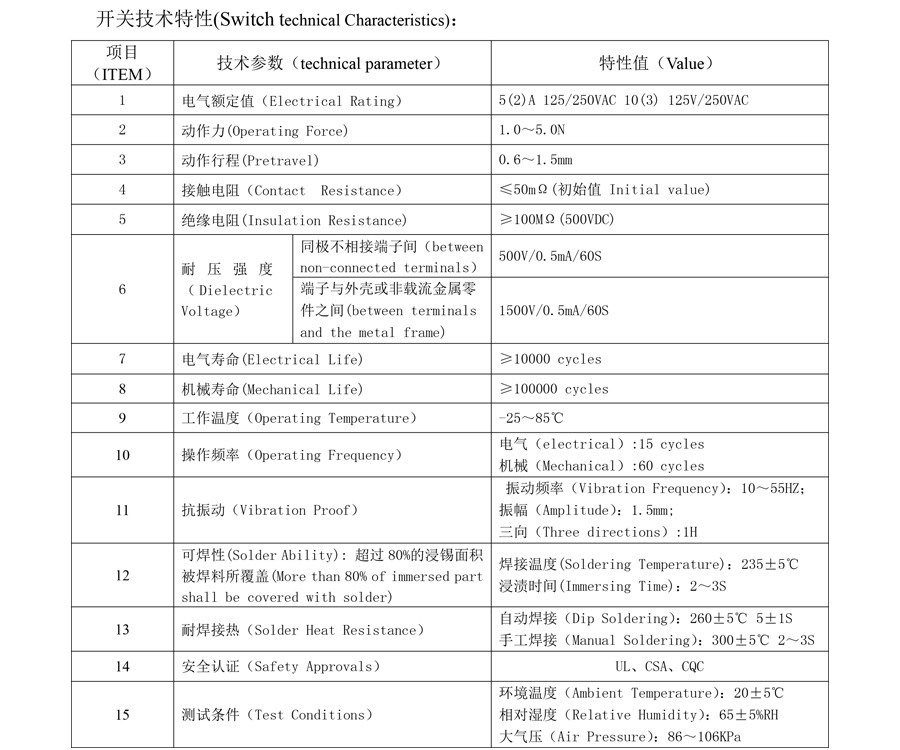

| Switch Technical Characteristics: | |||

| ITEM | Technical Parameter | Value | |

| 1 | Electrical Rating | 5 (2)A 125/250VAC 10(3) 125V/250VAC | |

| 2 | Operating Force | 1.0~5.0N | |

| 3 | Pretravel | 0.6~1.5mm | |

| 4 | Contact Resistance | ≤50mΩ Initial value | |

| 5 | Insulation Resistance | ≥100MΩ (500VDC) | |

| 6 |

Dielectric Voltage |

Between non-connected terminals |

500V/0.5mA/60S |

|

Between terminals and the metal frame |

1500V/0.5mA/60S | ||

| 7 | Electrical Life | ≥10000 cycles | |

| 8 | Mechanical Life | ≥100000 cycles | |

| 9 | Operating Temperature | -25~85℃ | |

| 10 | Operating Frequency |

Electrical :15 cycles Mechanical :60 cycles |

|

| 11 | Vibration Proof |

Vibration Frequency :10~55HZ; Amplitude :1.5mm; Three directions :1H |

|

| 12 |

Solder Ability : More than 80% of immersed part shall be covered with solder |

Soldering Temperature :235±5℃ Immersing Time : 2~3S |

|

| 13 | Solder Heat Resistance |

Dip Soldering :260±5℃ 5±1S Manual Soldering :300±5℃ 2~3S |

|

| 14 | Safety Approvals | UL、CSA、CQC | |

| 15 | Test Conditions |

Ambient Temperature :20±5℃ Relative Humidity :65±5%RH Air Pressure :86~106KPa |

|

Product Details

Relying on Yueqing Tongda's full-process industrial-grade quality control system, the FSK-14 undergoes multiple rigorous inspections from raw materials to finished products:

Raw Material Inspection: Contact material spectral analysis, spring fatigue strength testing, casing corrosion resistance testing, with core components certified to military-grade standards;

Production Inspection: Fully automated heavy-duty switch assembly line, key dimensional errors controlled within ±0.03mm, sealing performance 100% passed deep water immersion tests;

Finished Product Inspection: Fully passes 12 industrial-grade tests, including IP67 waterproof immersion, 1000 hours of salt spray corrosion, 50,000 durability presses, and 200Hz vibration shock.