- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

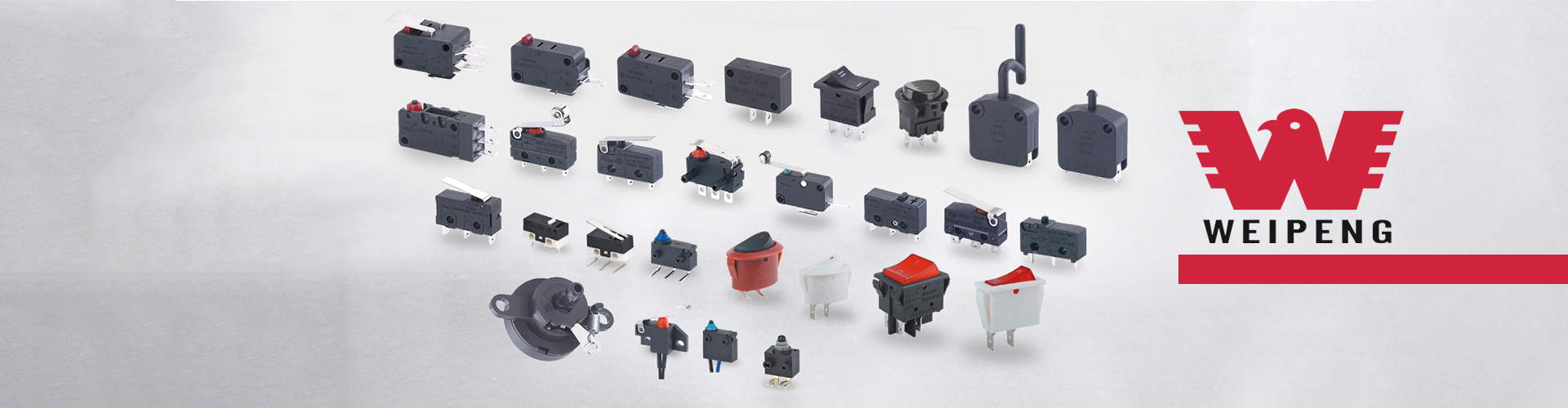

5A High-Temperature Resistant Smart Home Appliance Micro Switch

As a representative product of Yueqing Tongda Cable Power Plant that embodies the integration of core standardization and customization, the HK-04G-L switch is designed with the core principles of "stability, reliability, and scene compatibility." It incorporates 35 years of the company's switch manufacturing expertise, achieving multiple optimizations in electrical performance, protection levels, and user experience. The switch is widely applicable to scenarios such as smart home power distribution, industrial auxiliary equipment, and small medical instruments, making it a preferred circuit control component that balances universality with customization potential.

Model:HK-04G-LD-072

Send Inquiry

Micro Switch Introduction

The HK-04G-L switch fully adheres to Yueqing Tongda's "Three-Layer Quality Control System": Raw material stage. Each batch of silver-tin alloy contacts must undergo spectral component testing, and the casing must pass a 72-hour aging resistance test. Production stage, Relying on fully automated assembly lines, precise component fitting is achieved, with dimensional errors controlled within 0.02mm. Finished product stage: 100% of products undergo push-button lifespan testing, high and low-temperature cycling tests (-40°C to 85°C), and insulation resistance testing (≥100MΩ), maintaining a 100% factory pass rate.At the same time, the product enjoys a unified one-year warranty service from the company. If non-human-caused faults occur during use, customers can receive free replacement and technical support. Currently, the HK-04G-L switch has an annual sales volume of over 200,000 units. In addition to the domestic market, it is also exported to Europe and Southeast Asia with UL and VDE certifications, becoming a representative model of Yueqing Tongda's standardized products that combines both reputation and market competitiveness.Whether for basic circuit control requirements or mild customization scenarios, the HK-04G-L switch, with "stable performance and flexible adaptation" as its core, demonstrates Yueqing Tongda's technical strength in switch manufacturing and provides reliable circuit control support for equipment across various industries.

Micro Switch Application

Suitable for automotive electronic status monitoring.

Vehicle charging port: when inserting the charger, push the swing arm to connect the charging circuit, with silver alloy contacts compatible with a 12V/10A vehicle power supply;

Seat adjustment: the limit switch at the end of the slide rail detects the seat's extreme positions through the swing arm, preventing motor overload.

Micro Switch Specification

| Switch Technical Characteristics: | |||

| ITEM | Technical Parameter | Value | |

| 1 | Electrical Rating | 5(2)A 125V/250VAC 10(3)125V/250VAC | |

| 2 | Contact Resistance | ≤50mΩ Initial value | |

| 3 | Insulation Resistance | ≥100MΩ (500VDC) | |

| 4 |

Dielectric Voltage |

Between non-connected terminals |

500V/0.5mA/60S |

|

Between terminals and the metal frame |

1500V/0.5mA/60S | ||

| 5 | Electrical Life | ≥10000 cycles | |

| 6 | Mechanical Life | ≥100000 cycles | |

| 7 | Operating Temperature | -25~125℃ | |

| 8 | Operating Frequency |

Electrical :15 cycles Mechanical :60 cycles |

|

| 9 | Vibration Proof |

Vibration Frequency :10~55HZ; Amplitude :1.5mm; Three directions :1H |

|

| 10 |

Solder Ability : More than 80% of immersed part shall be covered with solder |

Soldering Temperature : 235±5℃ Immersing Time :2~3S |

|

| 11 | Solder Heat Resistance |

Dip Soldering :260±5℃ 5±1S Manual Soldering :300±5℃ 2~3S |

|

| 12 | Safety Approvals | UL、CSA、VDE、ENEC、CE | |

| 13 | Test Conditions |

Ambient Temperature :20±5℃ Relative Humidity :65±5%RH Air Pressure : 86~106KPa |

|

Tongda Wire Electric Micro USB Inline Power Switch Details