- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Waterproof Micro Switch Auto Parts

As a specialized product developed by Yueqing Tongda Cable Power Plant for high-precision control scenarios, the FSK-14 series waterproof micro switches feature 'IP67 protection and micron-level triggering accuracy' as their core competitive advantage. Combining the company's 35 years of experience in micro switch manufacturing, they are specifically designed for scenarios with strict requirements for sensitivity and sealing, such as water heaters, diving equipment, and emergency rescue machinery. With characteristics of 'precise triggering, reliable protection, and long-lasting durability,' they have become core components for precision circuit control in special environments.

Model:FSK-14-1X-10A-001

Send Inquiry

WEIPENG® is a leading Waterproof Micro Switch Auto Parts manufacturers, suppliers and exporter.

Tongda Waterproof Micro Switch Introduction

The FSK-14 series adopts an "integrated injection-molded sealing, multi-layer waterproof structure" design. The housing is made of weather-resistant PA66-GF25 reinforced nylon and is processed using a high-temperature, high-pressure one-piece molding technique to achieve a seamless exterior. Key interfaces are embedded with fluororubber sealing rings with a compression precisely controlled at 0.4-0.6mm, combined with an encapsulation sealing process to meet the IP67 protection standard. This allows for complete dust protection (IP6X) and immersion in 1 meter of water for 30 minutes without leakage (IPX7). Actual tests show that in underwater operations of diving equipment and in rescue pump spray environments, the internal component moisture rate is 0, thoroughly solving the traditional micro switch issue of "failure when exposed to water and jamming due to dust accumulation."

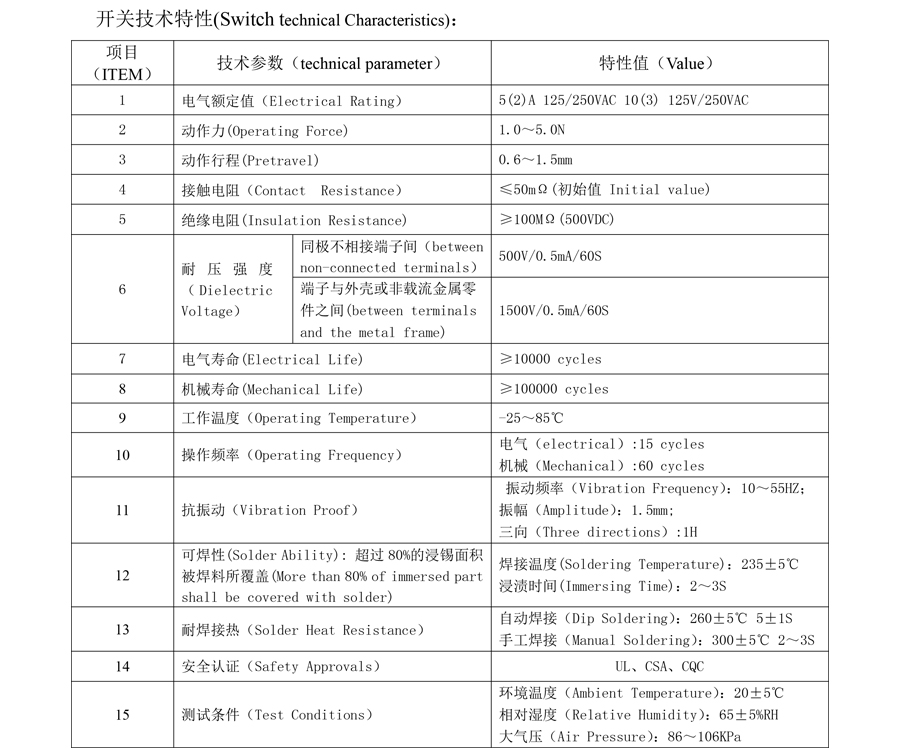

Tongda Waterproof Micro Switch Parameter (Specification)

| Switch Technical Characteristics: | |||

| ITEM | Technical Parameter | Value | |

| 1 | Electrical Rating | 5 (2)A 125/250VAC 10(3) 125V/250VAC | |

| 2 | Operating Force | 1.0~5.0N | |

| 3 | Pretravel | 0.6~1.5mm | |

| 4 | Contact Resistance | ≤50mΩ Initial value | |

| 5 | Insulation Resistance | ≥100MΩ (500VDC) | |

| 6 |

Dielectric Voltage |

Between non-connected terminals |

500V/0.5mA/60S |

|

Between terminals and the metal frame |

1500V/0.5mA/60S | ||

| 7 | Electrical Life | ≥10000 cycles | |

| 8 | Mechanical Life | ≥100000 cycles | |

| 9 | Operating Temperature | -25~85℃ | |

| 10 | Operating Frequency |

Electrical :15 cycles Mechanical :60 cycles |

|

| 11 | Vibration Proof |

Vibration Frequency :10~55HZ; Amplitude :1.5mm; Three directions :1H |

|

| 12 |

Solder Ability : More than 80% of immersed part shall be covered with solder |

Soldering Temperature :235±5℃ Immersing Time : 2~3S |

|

| 13 | Solder Heat Resistance |

Dip Soldering :260±5℃ 5±1S Manual Soldering :300±5℃ 2~3S |

|

| 14 | Safety Approvals | UL、CSA、CQC | |

| 15 | Test Conditions |

Ambient Temperature :20±5℃ Relative Humidity :65±5%RH Air Pressure :86~106KPa |

|

Tongda Micro Electrical Tongda Waterproof Micro Switch Push Button Auto Parts Detail